Application:

- Building exterior curtain walls

- Decoration and renovation additions for old buildings

- Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

- Shop door decorations

- Advertisement board display platforms and signboards

- Wallboard and ceilings for tunnels

- Website: https://vancopanel.com

A cooper composite panel is a type of mainstream divider enriching composite materials that come in various thicknesses, types, and are utilized for various purposes. It is portrayed by high mechanical quality, extraordinary unbending nature, sturdiness, and magnificent surface evenness. It is a lightweight composite material that has both low and high-temperature opposition, super strip quality, great smoothness, high caliber, and moderate cost.

All the copper composite panel items are made by coupling or holding two metal sheets upon a thick inside center made up of polyethylene (PE). Nonetheless, with regards to the point by point characterization of cooper composite panels, the essential standard changes to a limited degree.

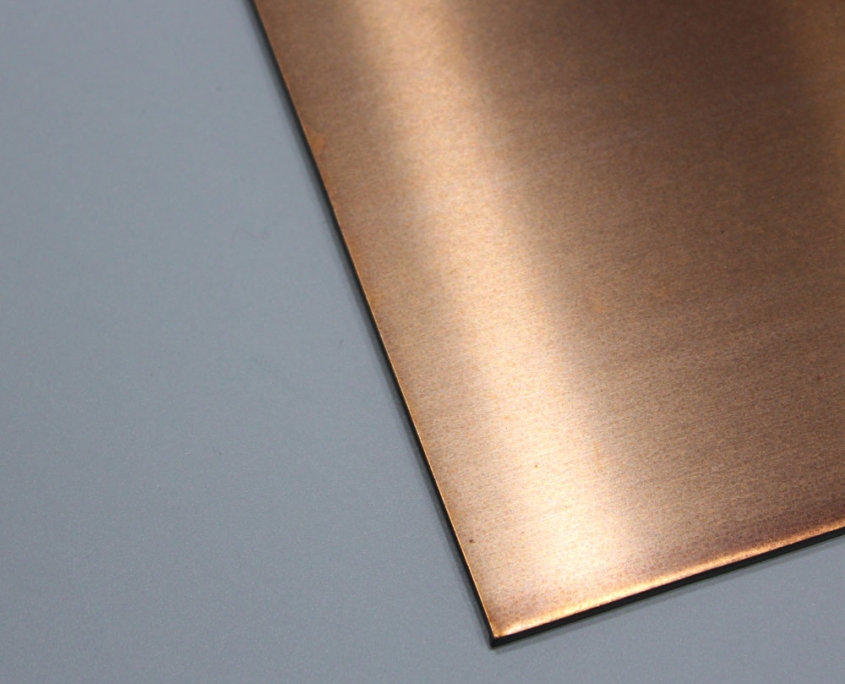

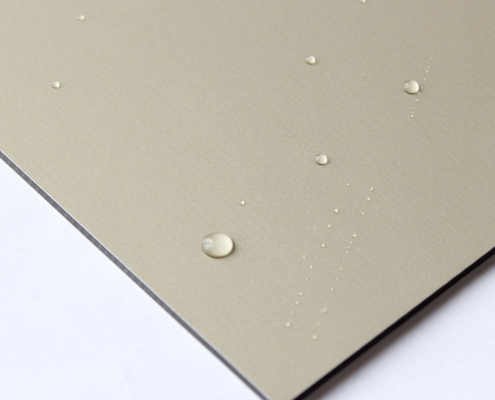

The copper composite panel (herewith call: CCP), the surface with the pure copper highlight, honorable disposition, no covering. Amazing climate opposition and simple to process. Lower cost than strong copper panels.

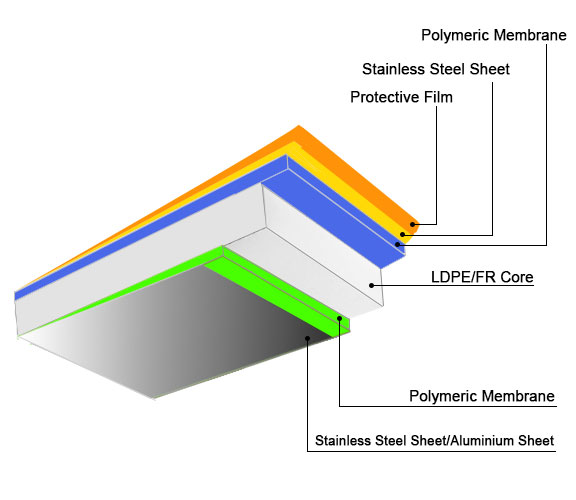

Structure:

Defensive film to ensure panel surface

Copper Sheet

Polymeric film composites the copper sheet onto the center.

LDPE/FR center is produced using low thickness polyethylene or flame-resistant evaluation materials.

Here is a portion of the notable highlights of the copper composite panel.

Thickness:

The thickness of the copper composite panel relies upon the brands and inclination. These panels come in different structures. By and large, PVDF copper composite panels are made in 3, 4, 5 and 6mm. Subsequently, you can browse various evaluations of solidarity and sturdiness reasonable for various requirements. The all-out thickness results from the mix of the metal curl, polymer film, and different materials.

Cladding:

The cooper composite panel is broadly utilized for cladding. The explanation is straightforward. The shifting thicknesses of this composite material are reasonable for cladding reason. Additionally, mechanical and physical properties of metal cladding settle on it the ideal decision for cladding.

Highlights and Applications:

There is a wide range of highlights of the copper composite panel as a material. The uncommon covering represents these highlights that recognize this specific material from different materials that have a place with the composite metal-based materials.

Above all else, the outside of the panel is smooth and level gratitude to the metal surface. What’s more, the metal surface makes it, considerably progressively, climate-safe. That is the reason this material is an incredible decision for cladding and outside employments. Likewise, highlights, for example, heat protection, sound protection, and imperviousness to fire add a completely new measurement to the cooper composite panel items. The territories of the utilization of cooper composite panels are adaptable. This material is every now and again utilized as a crude material in businesses and outsides of structures.

cooper composite panel is, in its pith, very like the cooper composite panel. The main distinction lies in the surface which further refines things such that makes the cooper composite panel a significant successful material.