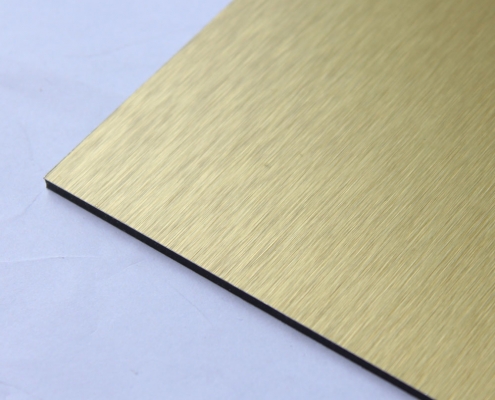

Aluminum composite panel(ACP) is a form of popular wall decorative composite materials that come in different thicknesses, types, and are used for different purposes. It is characterized by high mechanical strength, extreme rigidity, toughness, and superb surface flatness. It is a lightweight composite material that has both low and high-temperature resistance, super peel strength, excellent smoothness, high quality, and affordable price.

All the aluminum composite panel products are made by coupling or bonding two aluminum sheets upon a thick internal core made up of polyethylene (PE). However, when it comes to the detailed classification of aluminum composite panels, the basic principle changes to a certain extent. PVDF aluminum composite panel is one of the ACP types we will discuss in this article. This type of composite material follows the same basic principle behind the manufacture of the aluminum composite panels, with one key difference: the final product involves a coating of PVDF (Fluorocarbon). This feature accounts for some additional characteristics that make this type stand out from other aluminum composite panel products.

Here are some of the salient features of the PVDF aluminum composite panel.

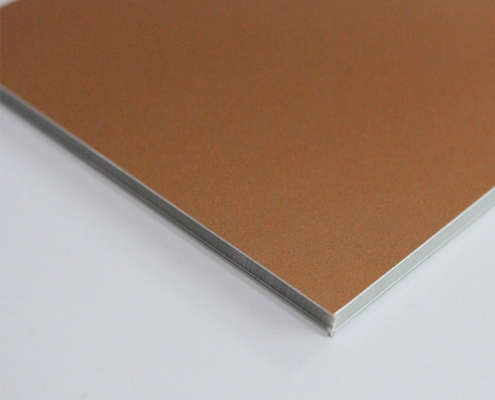

Structure:

Protective film to protect the panel surface

Clean PVDF coating or coating with colors applied to the aluminum sheet

Polymeric membrane composites the aluminum onto the core

LDPE/FR core is made from low-density polyethylene or fireproof grade materials

Thickness:

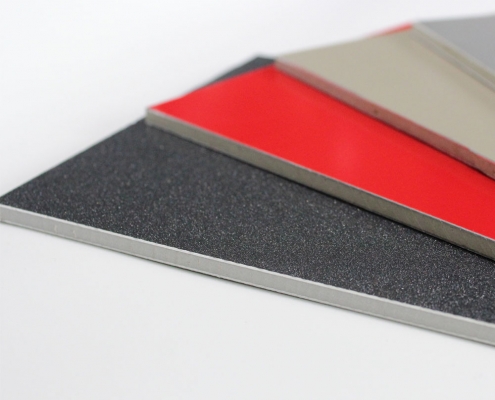

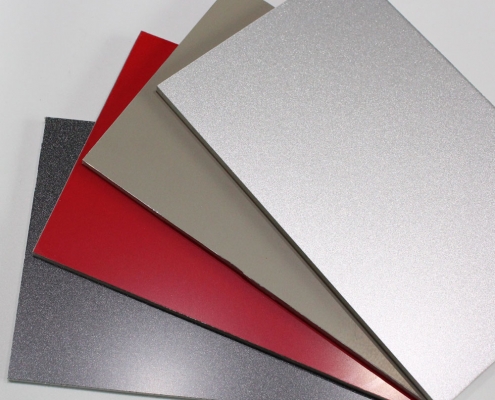

The thickness of the PVDF aluminum composite panel depends on the brands and preference. These panels come in various forms. In general, PVDF aluminum composite panels are manufactured in 3, 4, 5 and 6mm. As a result, you can choose from different grades of strength and durability suitable for different needs. The total thickness results from the combination of the aluminum coil, coating, polymer film, and other materials.

PVDF Coating:

PVDF coating is the element of this product that makes it stand out from all the other products in the aluminum composite panel product category. It is also the most important phase in the manufacturing process of this type of product because it supplements the aluminum composite panel and provides additional characteristics to this material. PVDF is essentially a mixture of several components. Those include fluorocarbon resins which contain fluorine enzyme, an ester solvent, paint, and alcohol. A mixture of these components makes a unique coating which gives more strength and resistance to this top-notch material.

Cladding:

PVDF aluminum composite panel is extensively used for cladding. The reason is simple. The varying thicknesses of this composite material are suitable for cladding purpose. Besides, mechanical and physical properties of PVDF make it the perfect choice for cladding.

Features and Applications:

There are many different features of PVDF panel as a material. The special coating accounts for these features that distinguish this particular material from the other materials that belong to the composite aluminum-based materials.

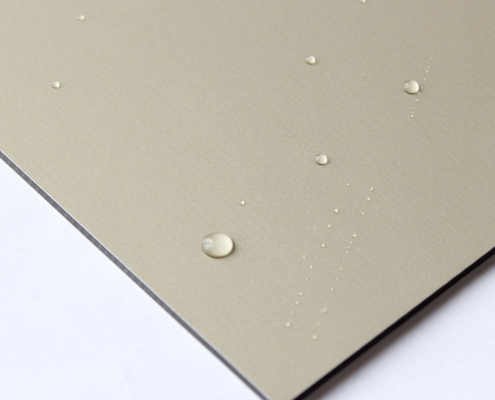

First of all, the surface of the panel is smooth and flat thanks to the fluorocarbon coating. In addition, the coating makes it, even more, weather resistant. That’s why this material is a great choice for cladding and exterior uses. Also, features such as heat insulation, sound insulation, and fire resistance add an entirely new dimension to the aluminum composite panel products. The areas of application of PVDF aluminum composite panel are versatile. This material is frequently used as a raw material in industries, advertisement boards, and exteriors of buildings.

PVDF aluminum composite panel is, in its essence, quite similar to the aluminum composite panel. The only difference lies in the coating which further refines things in a way that makes the PVDF panel quite an effective material.

Guarantee:

Warranty would be various based on different coating or special finish and it protects the panels from the manufacturing site to construction site.

vancopanel

vancopanel

vancopanel

vancopanel

vancopanel

vancopanel