Application:

- Building exterior curtain walls

- Decoration and renovation additions for old buildings

- Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

- Shop door decorations

- Advertisement board display platforms and signboards

- Wallboard and ceilings for tunnels

- Website: https://vancopanel.com

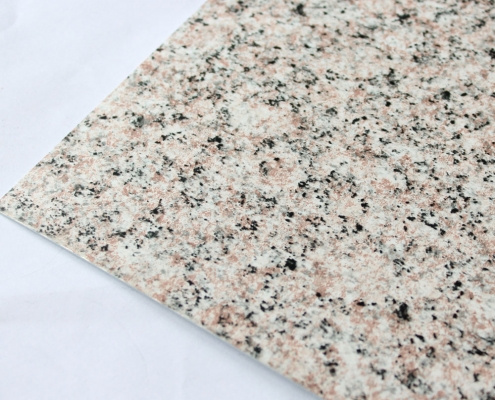

Aesthetically pleasing and vivid wood texture, fire-resistance, lightweight nature, exceptional surface gloss, flat and smooth surface, easy to process, acid-resistance, simple cleaning, simple manufacturing, alkali-resistance, easy maintenance, the possibility of choosing various uniform colors.

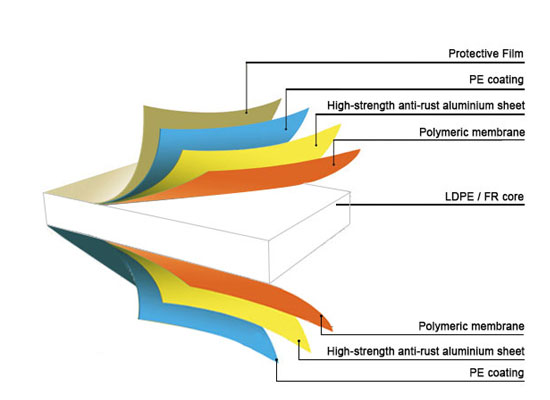

Structure:

- Protective film to protect panel surface

- Wooden texture coating applied on aluminium sheet.

- Polymeric membrane composites the aluminium onto core.

- LDPE/FR core is made from low density polyethylene or fireproof grade materials.

Specification

| Width | 1000mm-2000mm |

| Panel Thickness | 2mm-10mm |

| Aluminium Alloy | AA1100, AA3003 (other grade on requirement) |

| Aluminium Thickness | 0.18-1.0 mm |

| Coating | PE / PVDF/ FEVE |

| Core | LDPE / Fireproof |

| Length | 6000mm in maximum |

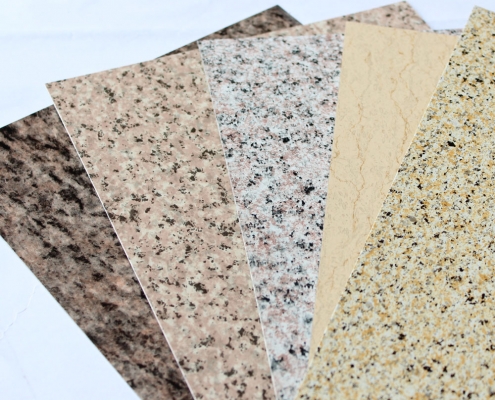

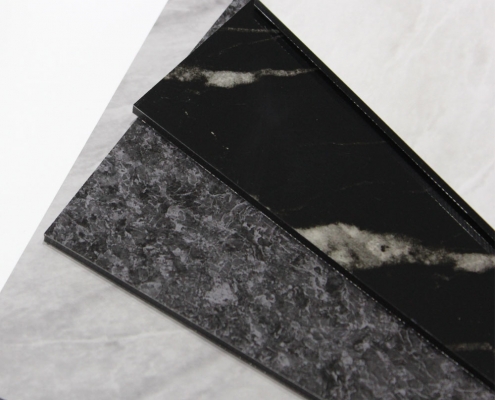

| Color | (Please contact us for more details) |

| MOQ | 1000 SQM/size/color |

| Brand / OEM | VANCO® / Customized |

| Delivery | 15 day after getting deposit and color confirmation |

| Payment Terms | T/T / L/C / Western Union / Paypal |

| Packing | Wooden Package or bulk loading |

The following are the most important features of wooden texture aluminum composite panels:

Specifications:

Both physical and chemical properties of Wooden Finish Aluminum Composite Board products are very good and contribute to the popularity of this material. As a result, this type of panels is considered one of the best composite panel products based on aluminum. It is a versatile material with lots of areas of application thanks to its varying thicknesses and size. The thickness ranges from 2mm to 6mm. As a result, these panels are flexible when it comes to different forms of usage. The standard width measures 1000mm. However, it is also flexible and different purposes require greater width. These panels can be up to 1575 mm wide. Similarly, the length of these panels can reach 6000mm. As a result, these aluminum panels are the first choice for many different applications.

Environmentally Friendly:

Wooden Finish Aluminum Composite Board is an environmentally friendly product. The wooden pattern is extremely popular among the customers. Yet, this synthetic pattern leads to a decrease in deforestation, preserving the natural wooden look and feel that is very popular especially in the interiors. Gradually, it is expected that these ACP products will replace a significant percentage of natural wood in interior and exterior applications.

Features and Applications:

Wooden Finish Aluminum Composite Board products are well known for their exceptional physical, mechanical, chemical, and aesthetic features. Those include excellent fireproof properties, sound insulation, strength, durability, smoothness, and surface flatness. On top of that, these ACP products are weather resistant. Therefore, they can be used both indoors and outdoors and weather conditions will not damage them for decades. That is the main reason why these types of panels are often chosen for garden applications, even in humid and cold climates.

Finally, this type of Wooden Finish Aluminum Composite Board is extremely popular in urban furniture applications, thanks to its extreme weather resistance. Moreover, the common applications of this type of panels include wallboards, kitchens, ceilings, balconies, shop face decorations, wall claddings, both interior and external.

Most noteworthy, these panels are environmentally friendly. They are offering an opportunity to replace natural wood and decrease deforestation. In the same time, the Wooden Finish Aluminum Composite Board types are very aesthetically valuable and allow the users to enjoy the traditional wooden look and feel. Thanks to a rather simple manufacturing process, the prices of these panels are reasonable. Taking into account that such a panel will last for decades, investing in these products is worth it.

Guarantee:

Warranty varies based on the coating type (PE or PVDF) to be applied to make the wooden texture.

vancopanel

vancopanel