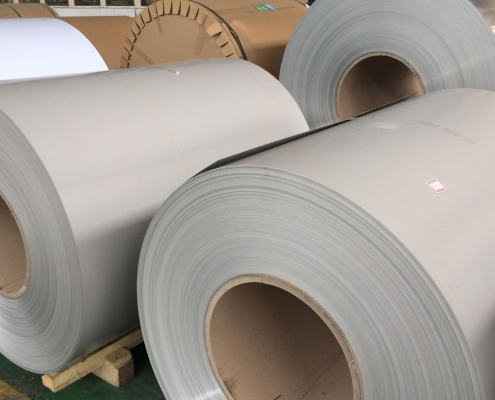

Aluminum is a valuable, convenient, and versatile metal. It comes in many different forms. Namely, through different processes, you can get aluminum sheets, thin foils, wires, and coils. This is the key feature that makes aluminum one of the most used materials in general. Moreover, it is very useful in different kinds of industries. In addition, there are many advantages of aluminum coil-over other coils, e.g. copper.

First of all, aluminum is a lightweight metal. This is significant because it is much lighter than steel or copper. As a result, it is widely used in different applications. Moreover, it increases its highly economical nature in comparison with some other, heavier metals.

Secondly, it is a strong and durable material regardless of the fact that it is lightweight.

Consequently, aluminum has a very wide area of application. You have some aluminum coil inside your air conditioning and your refrigerator. Moreover, we must emphasize that the aluminum coil is as good as the copper coil when it comes to performance levels. The lighter the material, the more economical. That’s why the HVAC industry prefers aluminum coils to copper coils.

On the other hand, copper coils do have their advantages over the aluminum coil. However, we must point out that the copper coil is, in comparison with the aluminum coil, definitely too expensive.

Electrical conductivity is another important aspect to consider. According to the experts, aluminum is as good as copper in many ways, including conductivity. Combined with this fact, aluminum is chosen more often than copper thanks to its cost-effectiveness.

Another very useful benefit of aluminum coil is the fact that it does not burn easily. In other words, this material can withstand high temperatures as well as high-temperature ranges. Its alloys can withstand heat up to 650 degrees Celsius. This property of aluminum plays a great role in its selection as the first-choice material for the production of condensing coils.

Aluminum has very good recyclable qualities, like copper. Aluminum never goes to waste. Even in cases of natural disasters like earthquakes and floods, aluminum structures were durable enough to withstand the damage. Moreover, damaged aluminum sheets are easily put into re-use, in different ways.

Even the thinnest coils can be easily produced from aluminum thanks to its excellent malleable qualities. Some aluminum foils are exceptionally thin. At the same time, they are very effective. Aluminum foils are very good at trapping and keeping heat. That’s why these products found their application in the food industry. They’re widely used for preservation of various items.

In conclusion, aluminum can be used for many purposes. Those vary from enormous structures, such as bridges where aluminum is used as a standard construction material, to aluminum coils inside billions of HVAC units around the world, to aluminum foils and their great role in the food industry and everyday life.