Application:

- Building exterior curtain walls

- Decoration and renovation additions for old buildings

- Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

- Shop door decorations

- Advertisement board display platforms and signboards

- Wallboard and ceilings for tunnels

- Website: https://vancopanel.com

PVDF Aluminum Composite Panel Details is a sort of a mainstream divider ornamental composite material that is generally utilized today. With its wonderful mechanical quality and generally excellent sturdiness, it is one of the most lightweight materials utilized for divider designs today. Be that as it may, PVDF Aluminum Composite Panel Details can’t just for divider improvements. It has generally excellent mechanical properties and along these lines has different regions of the application as well. It has an extraordinary unbending nature, both low and rather high-temperature obstruction, just as super strip quality. In addition, its phenomenal surface levelness and smoothness are the reasons why this material is energetically suggested for use in a wide range of zones of use. To summarize it, the PVDF Aluminum Composite Panel Details is a material of high caliber and moderate value that has a wide zone of utilization.

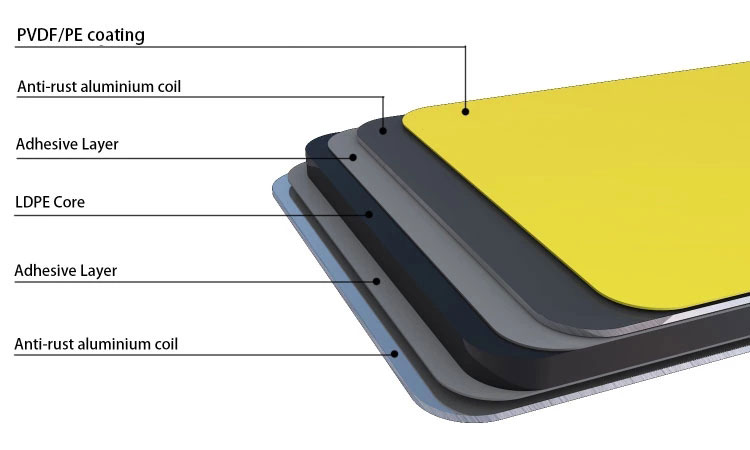

The entirety of the materials that have a place with this gathering, for example, the PVDF Aluminum Composite Panel Details items, are produced using two aluminum sheets that are coupled or reinforced upon a thick interior center. The center is produced using fire-retardant materials. It likewise contains a little level of polyethylene (PE). Such a structure represents unconventional highlights of this sort of aluminum composite panels.

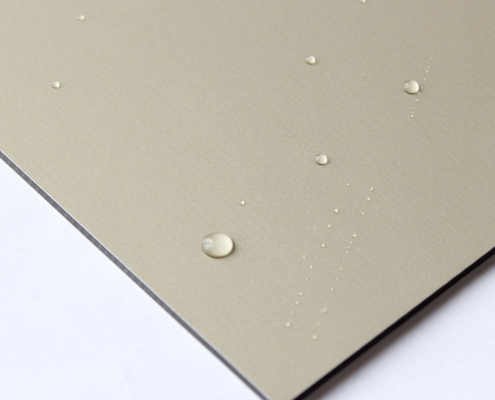

Key properties of the PVDF Aluminum Composite Panel Details incorporates high mechanical quality, which permits different modern applications, strength, and solidness, just as extraordinary unbending nature. As this is a lightweight material that has both low and high-temperature opposition, it is broadly utilized in building outsides also. It has a super strip quality, high caliber, magnificent surface smoothness and levelness, and a moderate cost. The covering represents another element, which is imperviousness to fire.

The same different sorts of the composite aluminum panels, the PVDF composite panels adhere to a general standard that says that two aluminum sheets and a thick inner PE center are made to frame a solitary material that demonstrations uniquely in contrast to every one of those materials independently. The polyethylene interior center records for unbending nature. With regards to PVDF Aluminum Composite Panel Details which contains fluorocarbon, its assembling procedure incorporates a significant distinction. In particular, it includes a covering of PVDF (Fluorocarbon). This specific advance records for improved highlights of the PVDF Aluminum Composite Panel Details when contrasted with different panels from this gathering.

Structure:

Defensive film to ensure panel surface

PVDF covering with clean or hues applied on aluminum sheet

Polymeric film composites the aluminum

LDPE/FR center is produced using low thickness polyethylene.

Here are probably the most conspicuous highlights of PVDF Aluminum Composite Panel Details.

Thickness:

PVDF Aluminum Composite Panel Details come in various thicknesses. This depends both on the planned reason or utilization of the panel and the brand. As a rule, PVDF covered panels are to some degree thicker than the normal aluminum composite panels. Basically, since there is another layer in its structure, these panels are thicker. They come in 3, 4, 5, and 6mm thicknesses. This is the reason PVDF aluminum composite panels are adaptable, helpful, and have various evaluations of solidarity and sturdiness.

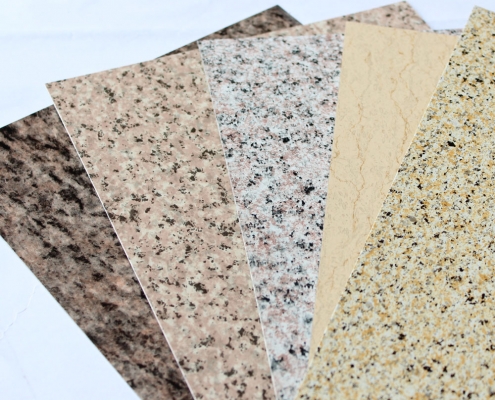

Fluorocarbon(PVDF) Coating:

Fluorocarbon(PVDF) covering is the single component that has the effect between this sort of panels and other aluminum composite panels. This material is a brilliant enhancement to aluminum. It improves its general highlights. PVDF is a blend of various parts, including fluorocarbon pitches which are the key fixing. Additionally, it contains liquor, paint, a fluorine compound, and ester dissolvable. The job of the PVDF covering is to give more quality and protection from the panel.

Cladding:

PVDF Aluminum Composite Panel Details items have a wide region of utilization. They are generally utilized as cladding. As these panels come in various thicknesses, are normally climate safe, and have excellent mechanical properties, they are ideal for building outsides.

Highlights and Applications:

The highlights of Fluorocarbon(PVDF) aluminum composite panel are fundamentally improving the general territory of the utilization of this item. Most importantly, the outside of the panel is much compliment on account of PVDF. The covering is liable for giving the most extreme levelness and smoothness. Another significant job of the PVDF covering is to make the material climate safe. Fluorocarbon is additionally significant for imperviousness to fire, heat protection, and sound protection. Thus, the territory of the utilization of the PVDF aluminum composite panel widens as it gets reasonable for objects requiring great fire security measures. All in all, the utilization of Fluorocarbon(PVDF) aluminum composite panel is flexible as it has an assortment of uses, including ventures, building outsides, and commercial sheets.

Fluorocarbon(PVDF) aluminum panel has a comparative assembling procedure and key highlights to the essential aluminum composite panel. In any case, there is one key contrast and that is the layer of PVDF in Aluminum Composite Panel or the fluorocarbon covering that essentially improves its mechanical and physical properties. It additionally refines the idea of this item, making the PVDF panel one of the best ones from the gathering of aluminum panels