Application:

- Building exterior curtain walls

- Decoration and renovation additions for old buildings

- Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

- Shop door decorations

- Advertisement board display platforms and signboards

- Wallboard and ceilings for tunnels

- Website: https://vancopanel.com

Key properties of the Aluminium composite panel outdoor includes very high mechanical strength, which allows various industrial applications, toughness, and durability, as well as extreme rigidity. As this is a lightweight material which has both low and high-temperature resistance, it is widely used in building exteriors as well. It has a super peel strength, very high quality, excellent surface smoothness and flatness, and an affordable price. The coating accounts for another feature, which is fire resistance.

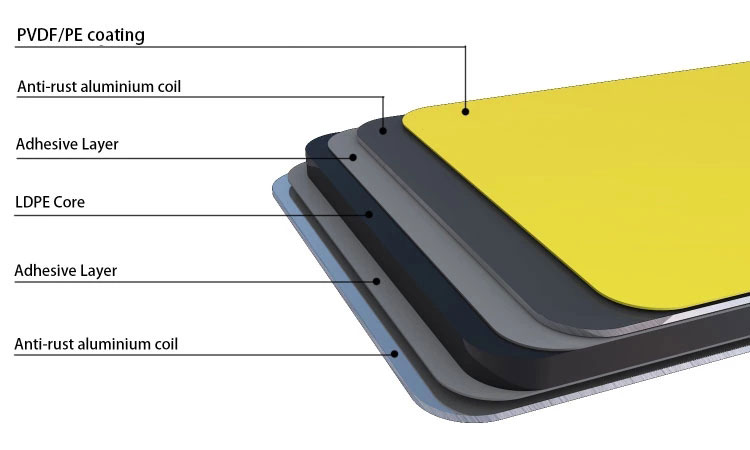

Structure:

- Protective film to protect panel surface

- PVDF coating with clean or colors applied on aluminium sheet

- Polymeric membrane composites the aluminium onto core

- LDPE/FR core is made from low density polyethylene or fireproof grade materials

Specification:

Width | 1000mm-2000mm |

Panel Thickness | 2mm-10mm |

Aluminium Alloy | AA1100, AA3003 |

Aluminium Thickness | 0.18-1.0 mm |

Coating | PVDF |

Core | LDPE / Fireproof / A2 non-combustible |

Length | 6000mm in maximum |

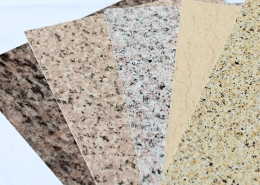

Color | Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror |

MOQ | 800 SQM/size/color |

Brand / OEM | VANCO® / Customized |

Delivery | 15 day after getting deposit and color confirmation |

Payment Terms | T/T / L/C / Western Union / Paypal |

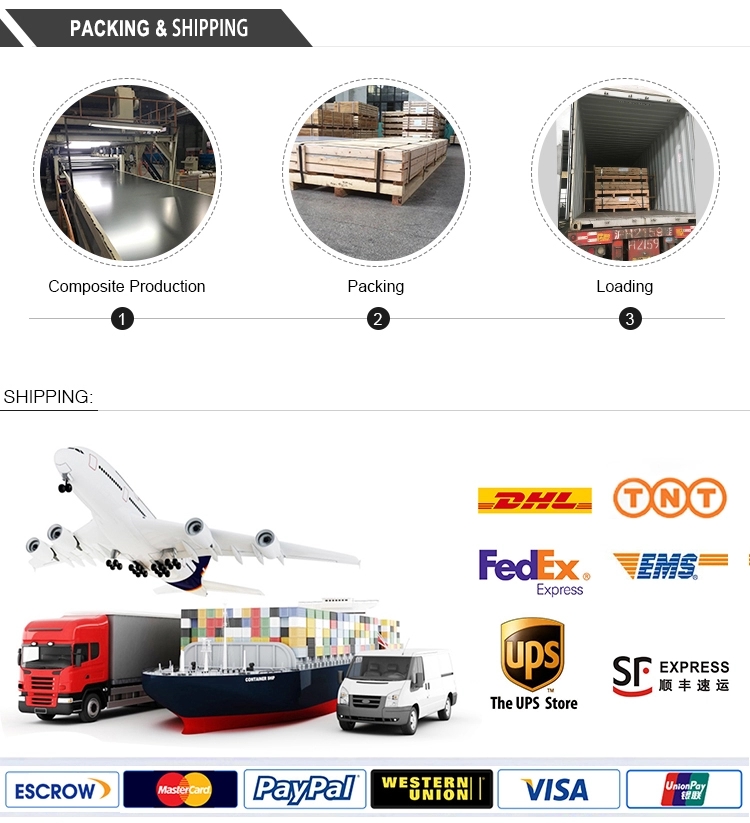

Packing | Wooden Package or bulk loading |

Here are some of the most prominent features of Aluminium composite panel outdoor.

Thickness:

Aluminium composite panel outdoor comes in different thicknesses. This depends both on the intended purpose or use of the panel and the brand. In general, PVDF coated panels are somewhat thicker than the regular aluminum composite panels. Simply since there is another layer in its structure, these panels are thicker. They come in 3, 4, 5, and 6mm thicknesses. This is why PVDF aluminum composite panels are versatile, convenient, and have different grades of strength and durability.

Fluorocarbon(PVDF) Coating:

Fluorocarbon(PVDF) coating is the single element that makes the difference between this type of panels and other aluminum composite panels. This material is an excellent supplement to aluminum. It improves its general features. PVDF is a mixture of different components, including fluorocarbon resins which are the key ingredient. Besides, it contains alcohol, paint, fluorine enzyme, and ester solvent. The role of the PVDF coating is to provide more strength and resistance to the panel.

Cladding:

Aluminium composite panel outdoor products have a wide area of application. They are usually used as cladding. As these panels come in different thicknesses, are usually weather-resistant, and have very good mechanical properties, they are perfect for building exteriors.

Features and Applications:

The features of Fluorocarbon(PVDF) aluminum composite panel are significantly improving the overall area of application of this product. First of all, the surface of the panel is even flatter thanks to PVDF. The coating is responsible for providing maximum flatness and smoothness. Another important role of the PVDF coating is to make the material weather-resistant. Fluorocarbon is also important for fire-resistance, heat insulation, and sound insulation. As a result, the area of application of the PVDF aluminum composite panel broadens as it becomes suitable for objects requiring good fire safety measures. In conclusion, use of Fluorocarbon(PVDF) aluminum composite panel is versatile as it has a variety of applications, including industries, building exteriors, and advertisement boards.

Fluorocarbon(PVDF) aluminum panel has a similar manufacturing process and key features to the basic aluminum composite panel. However, there is one key difference and that is the layer of PVDF in Aluminium composite panel outdoor or the fluorocarbon coating that significantly improves its mechanical and physical properties. It also refines the nature of this product, making the PVDF panel one of the most effective ones from the group of aluminum panels.

Guarantee:

15 years warranty is ensured for the Fluorocarbon (PVDF) coating aluminum panels which are used for exterior wall cladding and similar applications.