Application:

- Building exterior curtain walls

- Decoration and renovation additions for old buildings

- Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

- Shop door decorations

- Advertisement board display platforms and signboards

- Wallboard and ceilings for tunnels

- Website: https://vancopanel.com

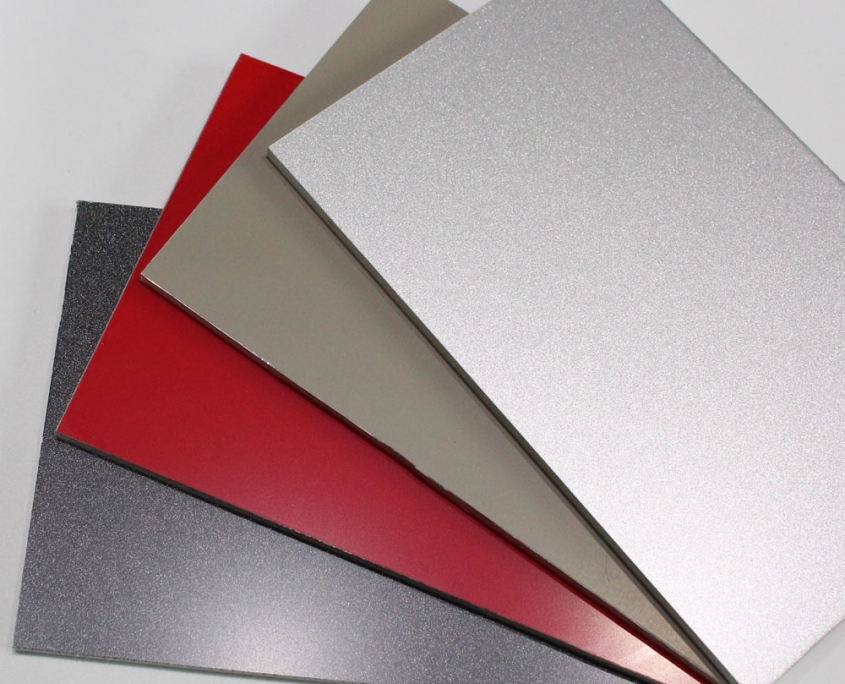

A2 aluminum composite cladding is a kind of a popular wall decorative composite material that is widely used today. With its superb mechanical strength and very good toughness, it is one of the most lightweight materials used for wall decorations today. However, A2 aluminum composite cladding is not used only for wall decorations. It has very good mechanical properties and therefore has other areas of the application too. It has an extreme rigidity, both very low and rather high-temperature resistance, as well as super peel strength. Moreover, its excellent surface flatness and smoothness are the reasons why this material is highly recommended for use in many different areas of application. To sum it up, the A2 aluminum composite cladding is a material of high quality and affordable price that has a wide area of application.

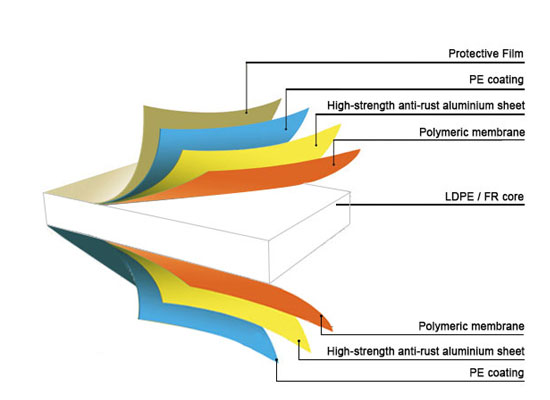

All of the materials that belong to this group, i.e. the A2 aluminum composite cladding products, are made from two aluminum sheets that are coupled or bonded upon a thick internal core. The core is made from fire-retardant materials. It also contains a small percentage of polyethylene (PE). Such a composition accounts for peculiar features of this type of aluminum composite panels.

Specification

| Width | 1000mm / 1220mm / 1250mm / 1500mm / 1575mm |

| Panel Thickness | 3mm, 4mm & 5mm |

| Aluminium Alloy | AA3003 / AA5005 |

| Aluminium Thickness | 0.15mm-0.70mm |

| Coating | PE / PVDF / Nano / FEVE |

| Fireproof Core | A2 mineral core |

| Length | 4000mm in maximum |

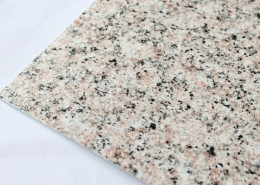

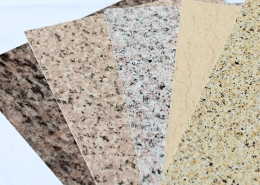

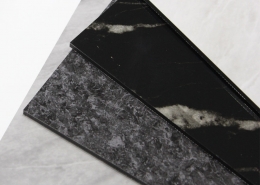

| Color | Solid / Metallic / Marble / Wooden / Brush / Glossy /Mirror |

| MOQ | 800 SQM/size/color |

| Brand / OEM | VANCO® / Customized |

| Delivery | 20 day after getting deposit and color confirmation |

| Payment Terms | T/T / L/C / Western Union / Paypal |

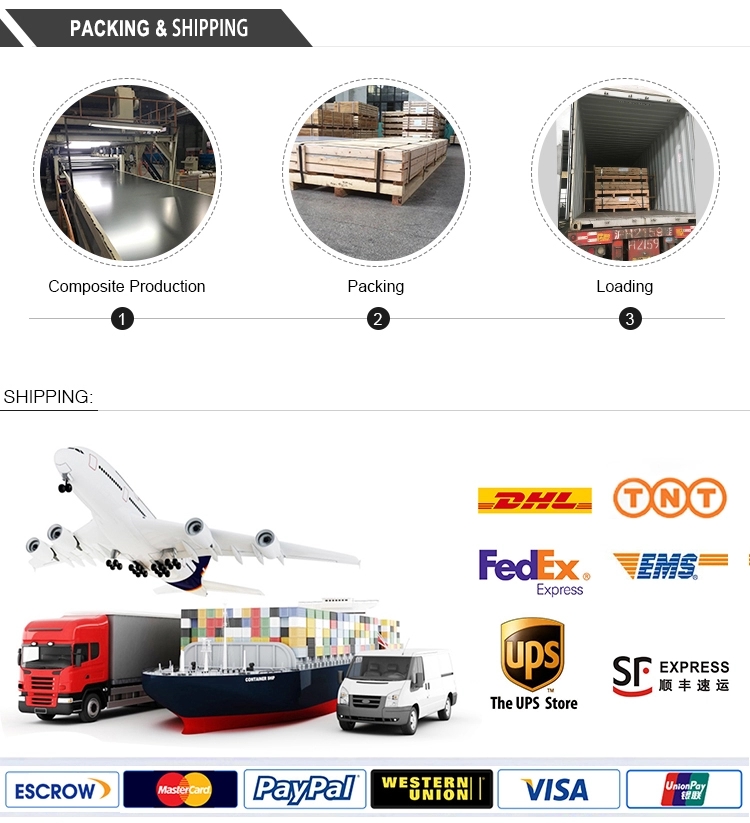

| Packing | Pallet or bulk loading |

These are the most prominent features of A2 aluminum composite cladding products.

Structure:

Protective film that protects the panel surface

- Clean or colored PVDF coating applied on the aluminum sheet

- Polymeric membrane composites on the aluminum core

- FR core is made from fireproof grade materials.

Thickness:

This material comes in various thicknesses. Namely, A2 aluminum composite cladding products are manufactured by different producers and brands. This is why they come in various forms. The total thickness of the final product, i.e. panel depends on the combination of the aluminum coil, coating, type and number of coatings, polymer film, as well as other materials that can enter the structure of the panel. Usually, A2 aluminum composite claddings come in 3, 4, 5, and 6mm thicknesses. Each thickness accounts for different physical and mechanical properties. Namely, the thicker the panel the greater the strength and durability of the particular panel.

Fluorocarbon (PVDF) Coating:

PVDF coating which is also known as the fluorocarbon coating is another important element in the aluminum panel structure. This is one of the layers that perfectly supplements the aluminum composite panel and its role. Fluorocarbon (PVDF) is a coating that is obtained by mixing several different components. Those include fluorocarbon resins, mainly containing the fluorine enzyme, alcohol, ester solvent, and paint. This coating is important as it provides more strength and resistance to the panel itself.

Features and Applications:

The features of A2 aluminum composite cladding products account for its wide area of application. Key features include a completely smooth and flat surface of the panel. The element of the structure that is important for the flatness is the coating. Furthermore, the Fluorocarbon (PVDF) has another important role, weather resistance. Today, we can even talk about heat and sound insulation, as well as fire resistance thanks to different coatings, mainly the PVDF. This opens new horizons regarding the use of the Aluminum composite panels. As a result, areas of application of the Fluorocarbon (PVDF) aluminum composite panels are very wide. Today, we mostly use it as a raw material in different kinds of industries. Besides, it is used for advertisement boards and claddings, facades, i.e. exteriors of buildings.

Additionally, A2 aluminum composite cladding types are suitable for environments that require a high fireproof grade. These panels are a good choice when it is necessary to improve the safety of people and animals, the building itself, and the environment.

Guarantee:

15 years warranty will be ensured for the Fluorocarbon (PVDF) coating used for exterior wall cladding or other applications.

Protective film that protects the panel surface

Protective film that protects the panel surface

vancopanel

vancopanel

vancopanel

vancopanel vancopanel

vancopanel